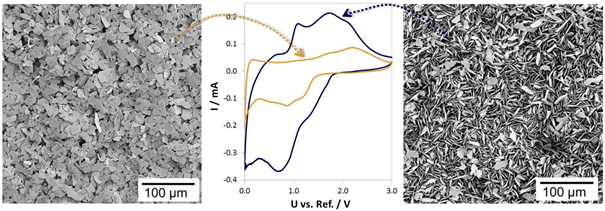

Novel thin film architectures with flake-like particles

Novel electrode architectures for lithium ion batteries and beyond

The group is developing new approaches for the structuring of secondary battery electrodes using flake-like particles as template or carrier of active material. Prior to deposition we have shown that it is possible to coat the flakes with a suitable lithium battery anode material (Cobalt Oxide) through either reduction or oxidation routes. On the one hand, by varying the solvent/binder system, we could show that the electrochemical performance of the resulting electrode can be modified due to variations in the electrode morphology. On the other hand, we have developed a completely new approach for the structuring of electrodes in which the active material is arranged on or between the flake-like particles which are perpendicular to the conducting substrate. Our method is based on a rather special application of electrophoretic deposition. We have demonstrated our process for commercial mica flakes (a component of pearlescent pigments) but it is likely that it can be applied to many other flake-like particles. We showed that when particles are vertically aligned on a substrate they form an electrode for a lithium ion battery which performs significantly better (higher capacity, faster charge/discharge) than the same amount of material lying flat. We believe that these properties result from the fact that access to the active material by lithium ions avoids tortuous routes if the electrode has the perpendicularly organised texture. Besides identifying and investigating the parameters which promote the vertical alignment of the flake particles we have sought to demonstrate the relevance of the electrode structuring concept to other devices e.g. dye-sensitized solar cells.

For battery fabrication and electrochemical testing we are very grateful for the kind collaboration of Prof. Julien Bachman (Chair of Chemistry of Thin Film Materials) and his team.